So I switched to a harness, backplate, and wing. I looked into it, and found I needed 10kg of lead - the downside of using twin 7s is that, unlike bigger twinsets, you don't get to shed your lead.

I melted down a 2kg block and made a nice P-weight out of it. That left me with 8kg still to find a home for.

My first location was the waist strap: I bought a couple of weight pockets, threaded them on, and dropped 4kg block weights into them. This worked, but it was awkward putting lead into them, took up a lot of space on the waist strap, and also gave me lousy trim: I was far too foot-heavy.

So I reasoned that moving the lead up higher would lead to better trim. I had some cambands lurking around, so I threaded the weight pockets onto them, and put them onto my cylinders.

This did indeed improve my trim, but it was very awkward to use on the RIB. It was difficult to remove the lead, and either the pockets or the buckles HAD to be on the back of the cylinders, where they were gauranteed to catch on the side of the RIB and make getting my gear back on board very difficult.

What made the camband experience even worse was, I already knew there was a much better way of doing it: The V-weight. This is where you melt your lead down and cast it into a V-shape that'll live between your cylinders and backplate. This puts the lead in just the right place, and keeps it totally out of the way.

The only problem with it is that there is no way of removing the lead without taking the whole rig apart. And since my sea diving is done off a RIB, I was not happy with making my rig unavoidably heavy, as it would make it very awkward to lift the rig back into the boat.

So I sat down and considered the problem: I needed a way of carrying lead on my back, that would allow me to remove it quickly and easily. The idea came to me suddenly that a V-weight worn on the OTHER SIDE of the cylinders would fulfill this criteria.

All I needed to do was find a reliable way of keeping the weight attached until I wanted to remove it. In a world full of weight belts made out of webbing, and weight harnesses that make heavy use of velcro, it wasn't long before I had the whole system designed in my head.

The lead would be melted down and cast into a shape that would fit snugly between my cylinders. I would put together a harness for it with a handle, to make it easy to get hold of.

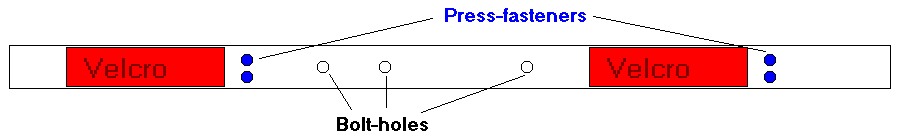

To prevent it going outwards, I would use a length of webbing. In the middle of this webbing would be two holes for the cylinder bolts to go through, and a third for the P-weight bolt.

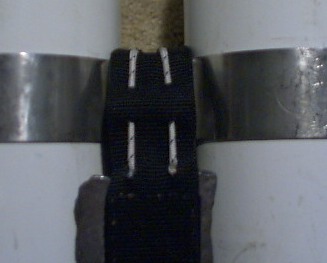

Each end of the webbing would go up the middle of the cylinders, over the steel bands, and down the other side. Where they overlapped, they would have velcro attached, and also some steel press-fasteners.

I put this idea together, and it seemed to work fine. The only problem I had was that the webbing wasn't quite tight enough to keep the weight from being able to move slightly. I eliminated this problem by adapting a weight-belt trick: I put some small holes into the webbing, and threaded bungee through them.

A few questions and answers:

Q: Is velcro really strong enough to reliably hold the weight?

A: Yes. The velcro is an industrial-strength variety, much better than the variety you'll find on clothing. A one-inch overlap is so strong I can't pull it apart with my hands, and I have about four inches on the webbing.

Q: Is the velcro attached reliably enough to hold the weight?

A: Yes. The velcro came with its own waterproof glue on it. I added Aquasure to this, just for good measure. Then when the glue had dried, I used monofilament (fishing line) to stitch the velcro in place. The ends are triple-stitched, the sides only single-stitched. The fishing line is rated for three pounds, which means every single stitch can support 3lbs of weight, and I have hundreds of stitches per piece of velcro.

Q: How much weight do you think can be safely supported by this system?

A: A lot! I have no idea exactly how much, but I tested the strength of the system by putting my entire wing system together, which consists of: a twinset; a 5lb backplate; 24lbs of lead; and a wing. I then lifted the whole thing up on a piece of rope, which was threaded through the webbing. It held with no trouble. So I think I'm safe in saying it will support the lead in perfect safety.

Q: What are the press-fasteners for?

A: Just for good measure, really. Velcro is of course designed to come apart when pulled upwards. The press-fasteners just make sure the velcro only comes apart when given a good yank. They're made of marine-grade stainless steel, so are totally corrosion-resistant.

Q: Doesn't the bungee weaken the system?

A: No, not really. It did mean putting a few holes in the webbing, but that's no major problem. The webbing was perfectly capable of keeping the weight in place without the bungee, the bungee just keeps the system that little bit tighter. If the bungee snaps, no problems will arise with the system.

Q: How easy is it to get the weight out? Does this count as a quick-release system?

A: It's very easy for anyone to get the lead out, but I don't think it really qualifies as quick-release. To remove the lead, you pull the end of the webbing up, pull the other end out of the way, take hold of the weight harness handle, and pull it out. Dead simple, but requiring a good three movements, as opposed to the typical one-move quick release system.

Q: Aren't non-quick-release weight system dangerous? Isn't it dangerous to carry weight you can't ditch yourself?

No, they aren't. The biggest danger with most quick-release weights is that they come off when you don't want them to. This system does not allow weights to fall out by accident. Also, I can remove the weight myself with very little trouble: It's not really hard to reach your own back.

Q: What do you call this system?

A: I call it the D-weight, for Ditchable. The webbing I refer to as a D-retainer.